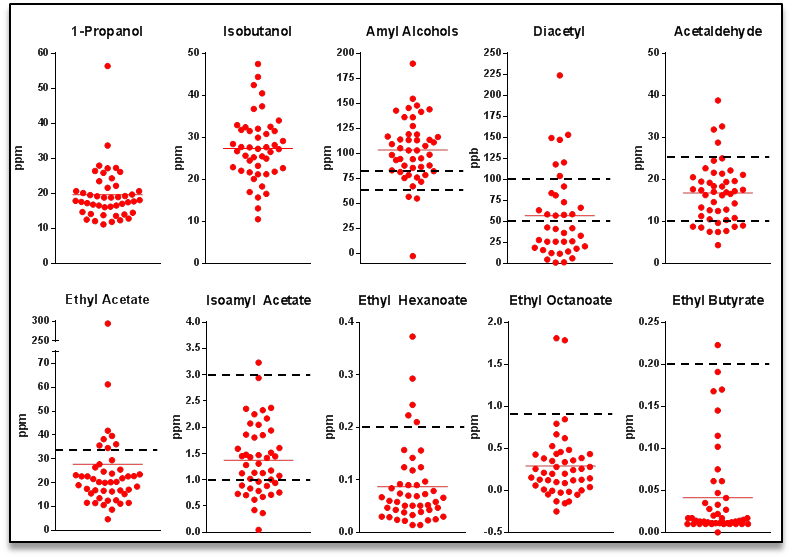

Designing the Experiment

In my previous post I introduced the brewing project to analyze Saccharomyces eubayanus as a brewing yeast. After collecting all of the data, they were analyzed using a concept known as design of experiments (DOE). Without delving into theory, the effects of multiple factors (e.g., starting gravity, mash temperature, mash time) on an output (e.g., attenuation) can be easily analyzed. Rather than analyzing the 10 different starting gravities (e.g., 1.025 to 1.070) mashed at eleven temperatures (e.g., 145-155°F) for three different times (e.g., 60 min, 90 min, 120 min) for a total 330 mashes, conditions can be randomized for a smaller experimental set, say 20 mash conditions, to generate a statistical response model to predict how these variables interact.

Optimizing Attenuation

In total, data from 49 beers representing 25 beer styles were submitted and analyzed.

Brewers recorded data for every aspect of their brewing process: recipe details, mash/steeping temperature, mash/steeping time, fermentation temperature, fermentation time, starting gravity, finishing gravity, yeast starter method, wort oxygenation method, and diacetyl detection.

While this experiment might be criticized for having too many uncontrollable variables, I argue that having the uncontrollability of multiple brewers actually helps control the entire experiment. If a trend emerged for a particular output, perhaps a phenolic flavor for example, definite characteristics of the yeast can then be made. Further, the performance of the yeast would be evaluated in real-world brewing scenarios, thereby demonstrating its practical utility as a brewing yeast.

Factors that impact attenuation were analyzed by first separating entries based on whether the brewers used malt extract or performed an all-grain mash. Eight beers were brewed partially or entirely with malt extract. Excluding a single outlier with 29.6% attenuation, the mean attenuation of these beers was 61.8% +/- 7.3%. Only one of these had fermentables from a mini-mash (6.2% Munich malt steeped at 150°F), and this had no noticeable effect on attenuation. No correlation could be made between the fermentation temperature and attenuation as the beer with the highest attenuation (74.5%) fermented at 70°F and the beers with the lowest (50% and 58%, again discounting the 29.6% beer) fermented at 67°F and 68°F.

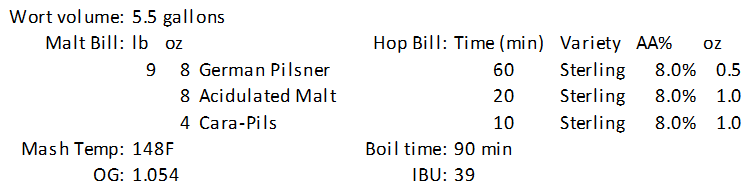

The mean attenuation of the all-grain beers was 64.7% +/- 11.1%. Of these, six attenuated 40-50%, four attenuated 51-60%, twenty-one attenuated 61-70%, seven attenuated 71-80%, one attenuated 82% and one attenuated 89%. The highest attenuation is most likely due to a 5 hour mash that started at 142°F and ended at an unknown, but much cooler temperature. The data for the all-grain beers were imported into JMP 11 software 5 to analyze the impact of the mash temperature, mash time, original gravity, percent specialty grains, fermentation temperature, and IBUs (since hops can inhibit yeast growth) on attenuation.

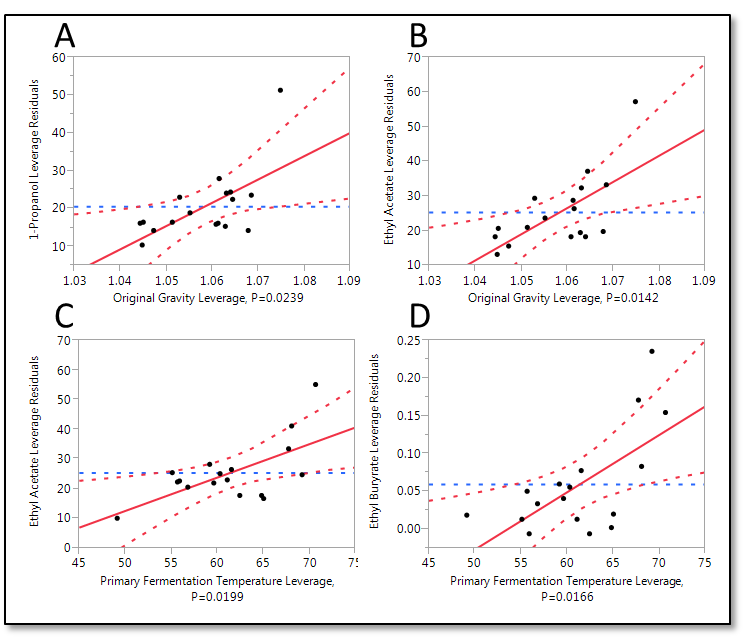

The impact of an individual effect in the context of the other effects on attenuation was analyzed using leveraging plots (Figure 1). The confidence curves (red dashed lines) indicate the significance of the effect on attenuation; curves that cross the blue line are considered significant. These data show that only the mash temperature has a significant impact on attenuation where a low mash temperature yields a more fermentable wort. The mash time, original gravity, and IBUs had no impact on attenuation and the fermentation temperature and percentage of specialty grains had borderline impacts.

Figure 1

The impact of the mash temperature on attenuation is not entirely surprising. Several groups have reported that, unlike S. cerevisiae, S. eubayanus lacks a maltotriose transporter (1, 2). Since lower mash temperatures generate less maltotriose molecules than higher mash temperatures, a more fermentable wort is achieved at low mash temperatures.

In the model, fermentation temperature had a borderline impact on attenuation. While an early report showed S. eubayanus does not ferment or grow very well at 72°F (1), a recent paper demonstrated that not only does S. eubayanus grow and ferment up to at least 86°F, at 68°F it grows and consumes sugars faster than S. cerevisiae (2). The data from these beers support the latter observation where multiple brewers demonstrated attenuation >80% at temperatures above 68°F. Both reports were in agreement that S. eubayanus grows well at low temperatures, and consistent with these reports, attenuation as high as 70% was seen by multiple brewers at 50-54°F.

In summary, S. eubayanus requires a wort produced from a low temperature mash containing few specialty malts to achieve high attenuation. The fermentation temperature had little impact on attenuation, allowing brewers to ferment over a wide range of temperatures.

Chemical Analysis of S. eubayanus Beers

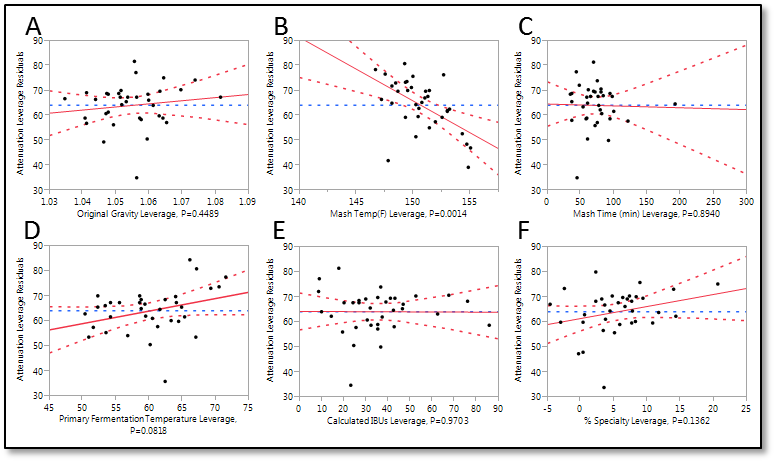

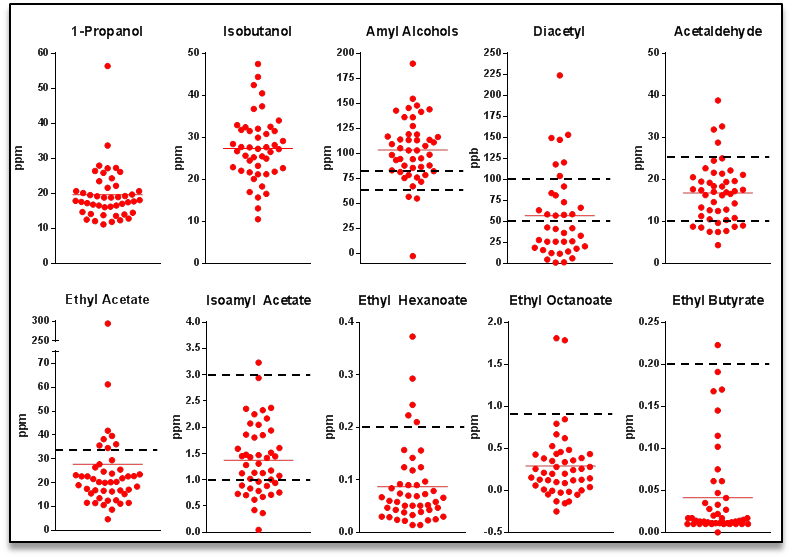

In addition to generously providing us yeast, White Labs also performed chemical analyses of the beers to determine the level of various flavor and aroma compounds in the beers. The data for all beers were plotted and the mean value for each compound was determined (Figure 2). Fusel alcohols (1-propanol and isobutanol) were very low. All but three beers had levels of amyl alcohols we

Figure 2

ll above the flavor detection threshold, which may account for the white wine-like flavors and aromas prevalent in a lot of the beers. A majority of the beers also had detectable levels of diacetyl. Acetaldehyde hovered between the range of flavor detection thresholds, and may have contributed to the apply flavors in the beers. Surprisingly, the levels of ethyl hexanoate and ethyl octanoate were below the threshold of detection in most samples, as these typically contribute to fresh-apple flavors. Perhaps S. eubayanus produces apple-like esters not typically produced by S. cerevisiae or S. pastorianus, and are therefore not part of the panel of compounds analyzed in beer. Ethyl acetate was detectable in most all beers. One beer in particular had an extreme level at 294 ppm. This beer was also the lowest scoring beer, and was described as cidery and astringent. The levels of isoamyl acetate were on the low end of detection, and likely contributed to some of the fruitiness, though no beer had an overt banana character (a large criticism in the Hefeweizen category). Ethyl butyrate was for the most part well below the threshold of detection.

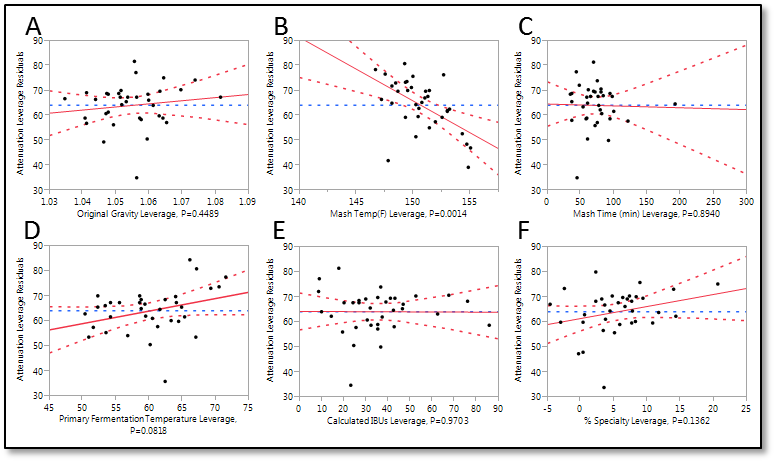

Figure 3

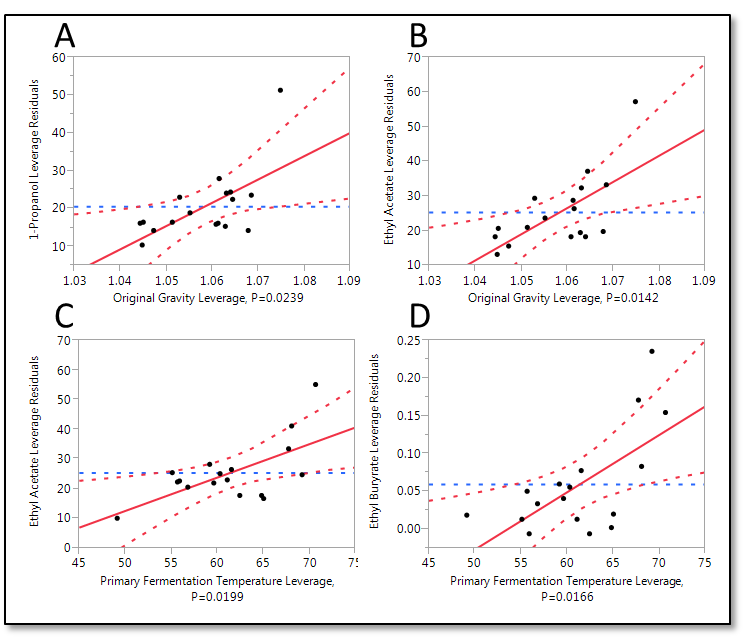

The influence of the original gravity, fermentation temperature, and fermentation time on the levels of all the compounds was analyzed by leveraging plots. Only ethyl acetate and 1-propanol were influenced by the original gravity. As the original gravity was increased, the levels of both tended to increase (Figure 3). The levels of ethyl acetate and ethyl butyrate also tended to increase as the primary fermentation temperature increased. No other compound appeared to be influenced by any other factor.

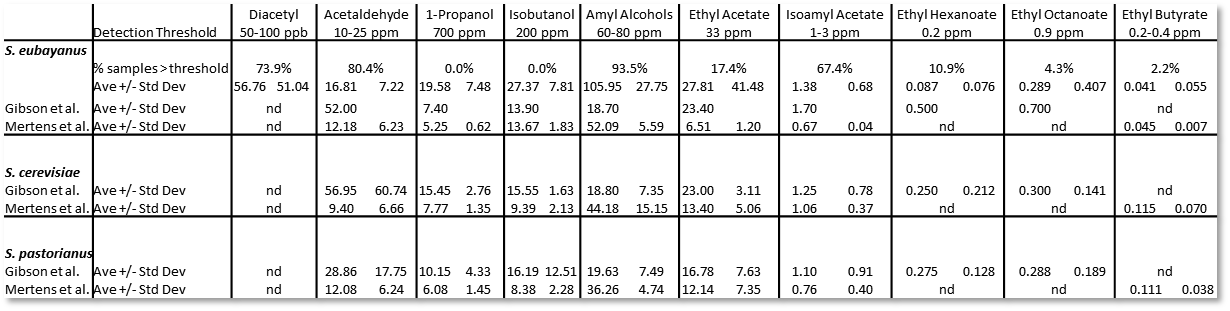

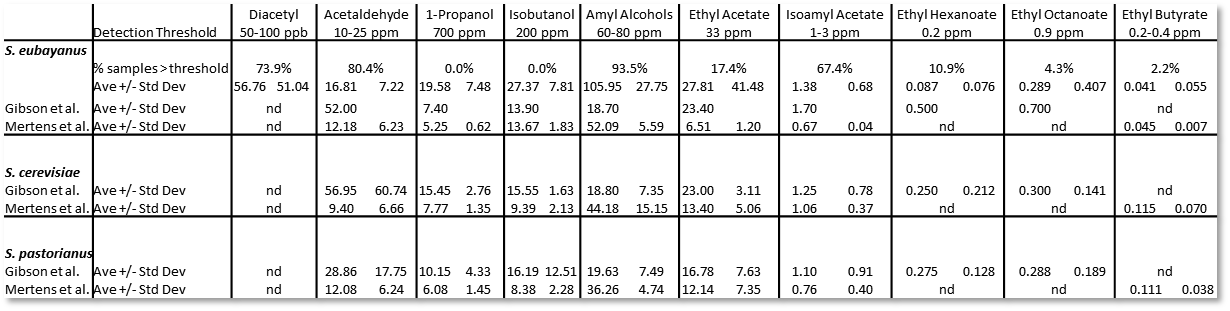

The mean values for each compound were compared to those published by Gibson et al. (1) and Mertens et al. (3) (Table 2).

Table 2

Overall, the data were consistent. These groups demonstrated that compared to S. cerevisiae and S. pastorianus, S. eubayanus produced similar or less amounts of acetaldehyde, and these levels were similar to the beers in this study. They also found similar amounts of higher alcohols (1-propanol, isobutanol, isoamyl alcohol) between the three species of yeast. The beers in this study, however, had much greater levels of amyl alcohols than what these groups reported. The levels of ethyl acetate, isoamyl acetate, and ethyl butyrate were similar between yeast in all of the studies. Gibson et al. reported the esters ethyl hexanoate and ethyl octanoate were 0.2-0.3 ppm higher than S. cerevisiae and S. pastorianus. However, the levels in our beers were similar to those seen in S. cerevisiae and S. pastorianus.

References

1. Gibson, B. R., Storgards, E., Krogerus, K., and Vidgren, V. Comparative physiology and fermentation performance of Saaz and Frohberg lager yeast strains and the parental species Saccharomyces eubayanus. Yeast 30(7), 255-266. 2013.

2. Hebly, M., Brickwedde, A., Bolat, I., Driessen, M. R., de Hulster, E. A., van den Broek, M., Pronk, J. T., Geertman, J. M., Daran, J. M., and Daran-Lapujade, P. S. cerevisiae x S. eubayanus interspecific hybrid, the best of both worlds and beyond. FEMS Yeast Res 15(3). 2015.

3. Mertens, S., Steensels, J., Saels, V., De, Rouck G., Aerts, G., and Verstrepen, K. J. A Large Set of Newly Created Interspecific Saccharomyces Hybrids Increases Aromatic Diversity in Lager Beers. Appl.Environ.Microbiol. 81(23), 8202-8214. 2015.

The Best of Show beer was a Brown Porter brewed by Chris Clair (BUZZ, West Chester, PA) who received a score of 37.5 and received a gift certificate from Artisan Homebrew Shop. The Runner-up and Second Runner-up beers sponsored by Northern Brewer and Yeast Bay were an India Pale Lager and American Pale Ale, both brewed by Steve Groff (Main Line Brewers Association, Ardmore, PA). It is interesting to note that Steve’s beers were actually a split batch where the runner up beer was fermented at 50°F and scored a 39 and the second runner up was fermented at 60°F and scored a 33. Both brewers skillfully executed their beers and demonstrated the quality of beer that can be made with S. eubayanus.

The Best of Show beer was a Brown Porter brewed by Chris Clair (BUZZ, West Chester, PA) who received a score of 37.5 and received a gift certificate from Artisan Homebrew Shop. The Runner-up and Second Runner-up beers sponsored by Northern Brewer and Yeast Bay were an India Pale Lager and American Pale Ale, both brewed by Steve Groff (Main Line Brewers Association, Ardmore, PA). It is interesting to note that Steve’s beers were actually a split batch where the runner up beer was fermented at 50°F and scored a 39 and the second runner up was fermented at 60°F and scored a 33. Both brewers skillfully executed their beers and demonstrated the quality of beer that can be made with S. eubayanus.

I never really questioned the 5-gallon standard prevalent among homebrewers. That’s the size of the first kit I bought, and beyond doubling to 10 gallons every once in a while, I never tried out different batch sizes. The 5-gallon standard is a standard for a reason. The volume fits in readily available 6.5 gallon food-grade buckets and in 5-gallon glass or plastic carboys. It also makes 2 cases of beer or completely fills a corny keg.

I never really questioned the 5-gallon standard prevalent among homebrewers. That’s the size of the first kit I bought, and beyond doubling to 10 gallons every once in a while, I never tried out different batch sizes. The 5-gallon standard is a standard for a reason. The volume fits in readily available 6.5 gallon food-grade buckets and in 5-gallon glass or plastic carboys. It also makes 2 cases of beer or completely fills a corny keg. The kit came with a 1 gallon glass fermenter, airlock, tubing, thermometer, tubing clamp, and sanitizer. I was surprised that the kit was an all-grain recipe wother 2.5 lb of crushed grain. I assumed most beginner’s kits are extract kits. But I guess their rational is the batch size is small enough to mash in a stock pot.

The kit came with a 1 gallon glass fermenter, airlock, tubing, thermometer, tubing clamp, and sanitizer. I was surprised that the kit was an all-grain recipe wother 2.5 lb of crushed grain. I assumed most beginner’s kits are extract kits. But I guess their rational is the batch size is small enough to mash in a stock pot. Beyond what came with the kit, I needed a few extra items. I decided to forgo the stock pot and used a small cooler as my mash tun. I used an Erlenmeyer flask to measure the water, a strainer for straining the wort from the grain, and a stock pot to boil the wort. I also grabbed a funnel for transferring wort into the fermentor. Besides the flask, all these items are laying around most kitchens, and should make it easy for anyone to just whip up a small batch of beer with no need to invest in brewing equipment. So far, this small batch brewing seemed like a great idea.

Beyond what came with the kit, I needed a few extra items. I decided to forgo the stock pot and used a small cooler as my mash tun. I used an Erlenmeyer flask to measure the water, a strainer for straining the wort from the grain, and a stock pot to boil the wort. I also grabbed a funnel for transferring wort into the fermentor. Besides the flask, all these items are laying around most kitchens, and should make it easy for anyone to just whip up a small batch of beer with no need to invest in brewing equipment. So far, this small batch brewing seemed like a great idea. I mashed for an hour per the instructions, and strained the wort into the pot. Apparently the cooler was not designed to pour liquid, and I created a mess by having wort stream down the side of it. Not pleased that I lost some of my first runnings – strike one. Especially since the total volume I collected was just over a half gallon. At this scale, every ounce counts. After cleaning up my mess I returned the grain to the cooler and batch sparked with another half gallon of water. Again, transferring and straining the wort proved messy. Nonetheless I got (almost) everything transfered.

I mashed for an hour per the instructions, and strained the wort into the pot. Apparently the cooler was not designed to pour liquid, and I created a mess by having wort stream down the side of it. Not pleased that I lost some of my first runnings – strike one. Especially since the total volume I collected was just over a half gallon. At this scale, every ounce counts. After cleaning up my mess I returned the grain to the cooler and batch sparked with another half gallon of water. Again, transferring and straining the wort proved messy. Nonetheless I got (almost) everything transfered. At this small scale and without the use of a false bottom, there really is no way to vorlauf. So the wort you collect is a cloudy mess. I tried to strain the wort back through the grain bed in the strainer, (per the instructions), but that did not clear up the wort – strike two.

At this small scale and without the use of a false bottom, there really is no way to vorlauf. So the wort you collect is a cloudy mess. I tried to strain the wort back through the grain bed in the strainer, (per the instructions), but that did not clear up the wort – strike two. The instructions say to fill to 1 gallon, but I left a little bit of headspace as I expected the yeast to foam. However, even reducing the headspace some did not protect me from an overflowing mess – strike three.

The instructions say to fill to 1 gallon, but I left a little bit of headspace as I expected the yeast to foam. However, even reducing the headspace some did not protect me from an overflowing mess – strike three. After a couple days the foaming subsided and only lost a little beer.

After a couple days the foaming subsided and only lost a little beer. Currently, there is very little information about brewing beer with S. eubayanus. A search of journal articles on

Currently, there is very little information about brewing beer with S. eubayanus. A search of journal articles on